How to Choose the Right Switchgear for Your Industrial Applications

In today’s industrial landscape, ensuring safe and efficient power distribution is critical. Whether you’re designing a new facility or upgrading an existing one, selecting the right switchgear is vital for operational safety, load management, and system reliability.

But with so many types, ratings, and features, how do you make the right choice?

This guide will walk you through the essential factors to consider when selecting industrial switchgear for your application.

What Is Switchgear?

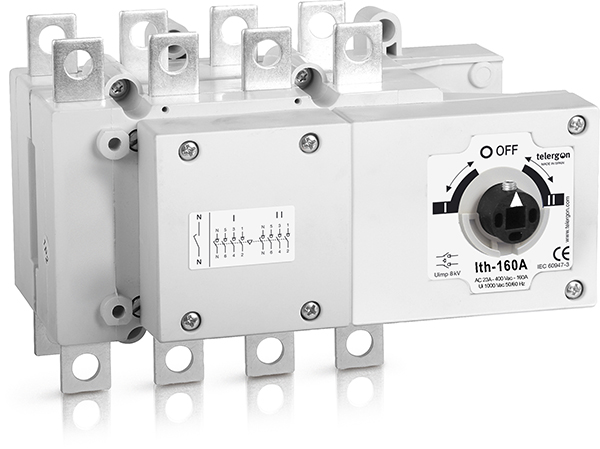

Switchgear is a general term for devices that control, protect, and isolate electrical equipment. It includes circuit breakers, disconnect switches, fuses, relays, and control panels. In industrial applications, switchgear is used to protect motors, generators, transformers, and distribution lines.

Factors to Consider When Choosing the Right Switchgear

Switchgear plays a crucial role in controlling, protecting, and isolating electrical equipment. Whether you’re setting up a new system or upgrading an existing one, choosing the Switchgear for industrial applications operational safety, system longevity, and minimal downtime. Here are the key factors to keep in mind when selecting the right switchgear for your application:

1. Application Type & Load Requirements

Start by identifying where and how the switchgear will be used:

- Is it for power distribution, motor control, or emergency backup?

- Determine the type of loads involved — inductive, resistive, or capacitive.

- Understand peak demand, starting currents, and potential fault levels.

This assessment helps in choosing between low-voltage, medium-voltage, or high-voltage switchgear suitable for your setup.

2. Current and Voltage Ratings

The switchgear must handle your system’s maximum current and voltage safely. Focus on:

- Rated current (Amperes)

- Operating voltage (Volts)

- Short-circuit withstand capacity

It’s essential to plan for future load expansion by selecting switchgear that offers a buffer in its electrical rating.

3. Switching Mechanism Type

The switching mechanism depends on how frequently and in what way you intend to operate the system:

- Manual mechanisms are ideal for occasional operations and simpler systems.

- Contactor-based systems are best for setups that need frequent on/off cycles, like motors.

Automatic transfer switches (ATS) are used in power backup systems to seamlessly shift load during outages.

Choosing the right mechanism ensures operational efficiency, safety, and ease of maintenance.

4. Compliance with Standards

Safety and legal compliance should never be compromised. Ensure the switchgear follows:

- IEC 60947,

- IS/IEC 61439,

- UL 508

- BIS certifications (for India)

Products aligned with these standards provide long-term reliability and peace of mind in critical applications.

5. Environmental and Installation Conditions

The physical environment greatly affects switchgear performance. Assess:

- Indoor vs. outdoor use

- Exposure to dust, humidity, or chemicals

- Ambient temperature extremes

Depending on conditions, look for IP-rated enclosures, corrosion resistance, and installation options like wall-mounting or base-mounting.

6. Maintenance and Serviceability

Ease of maintenance is crucial, especially in industrial applications. Opt for switchgear that features:

- Modular design

- Clear labeling

- Accessible internal componen

This helps reduce downtime and improves safety during inspection or servicing.

7. Scalability and Customization

Business and infrastructure need to grow over time. Select systems that support:

- Modular expansion

- Add-ons like auxiliary contacts, lockable handles

- Remote monitoring features

This future-proofs your investment and allows smoother upgrades without system overhaul.

Why Gorlan India

Choosing the right switchgear goes beyond specs — it’s about finding a balance of safety, flexibility, and performance. By considering load requirements, environment, compliance, and future scalability, you can ensure long-term reliability and protection for your industrial operations.

At Gorlan India, we offer a wide range of certified switchgear products and accessories, built for demanding industrial environments. With 25+ years of industry experience, we help you make the right choice — safely and smartly.

Have questions or need guidance in choosing the right switchgear for your application? Connect with us today and make the smart, safe choice with Gorlan India.

Related News

New S3 Series: AC Compact Switch-Disconnectors

New S3 series of compact modular switch-disconnectors, a range of products specifically designed to meet...

We’re exhibiting at ELECRAMA-2025

We are going to participate in ELECRAMA 2025, the leading global exhibition for the electrical...